Why I Started Making After Office Hours

How I Started a Creative Side Hustle Using Digital Fabrication— and How I Balance It with a Full-Time Job While Sharing My Journey

For as long as I can remember, I’ve been drawn to designing and making things.

I’ve always loved the entire process of bringing ideas to life—from initial concepts and research to creating something tangible that I can hold in my hands.

This passion is what led me to study Mechanical Engineering when I started university back in 2011.

I had a lot of interests, but one thing stood out above all: I wanted to "be an inventor" (whatever that was supposed to mean). That dream of building something useful always fueled my curiosity.

Fast forward to 2025, and my career path has taken me through vastly different roles—each one sparking new ideas and teaching me valuable lessons.

Looking back, I’m glad I explored so many different things. But one takeaway stands out: I need to create, daily.

It’s not just a hobby or a skillset; it’s something I have to do.

When I transitioned into software development, I found a new way to exercise my creativity. I love coding, problem-solving, and the satisfaction of building functioning stuff from scratch.

However, as much as I enjoy it, I’ve come to realize that I also need to create physical, tangible stuff.

Enter Digital Fabrication methods

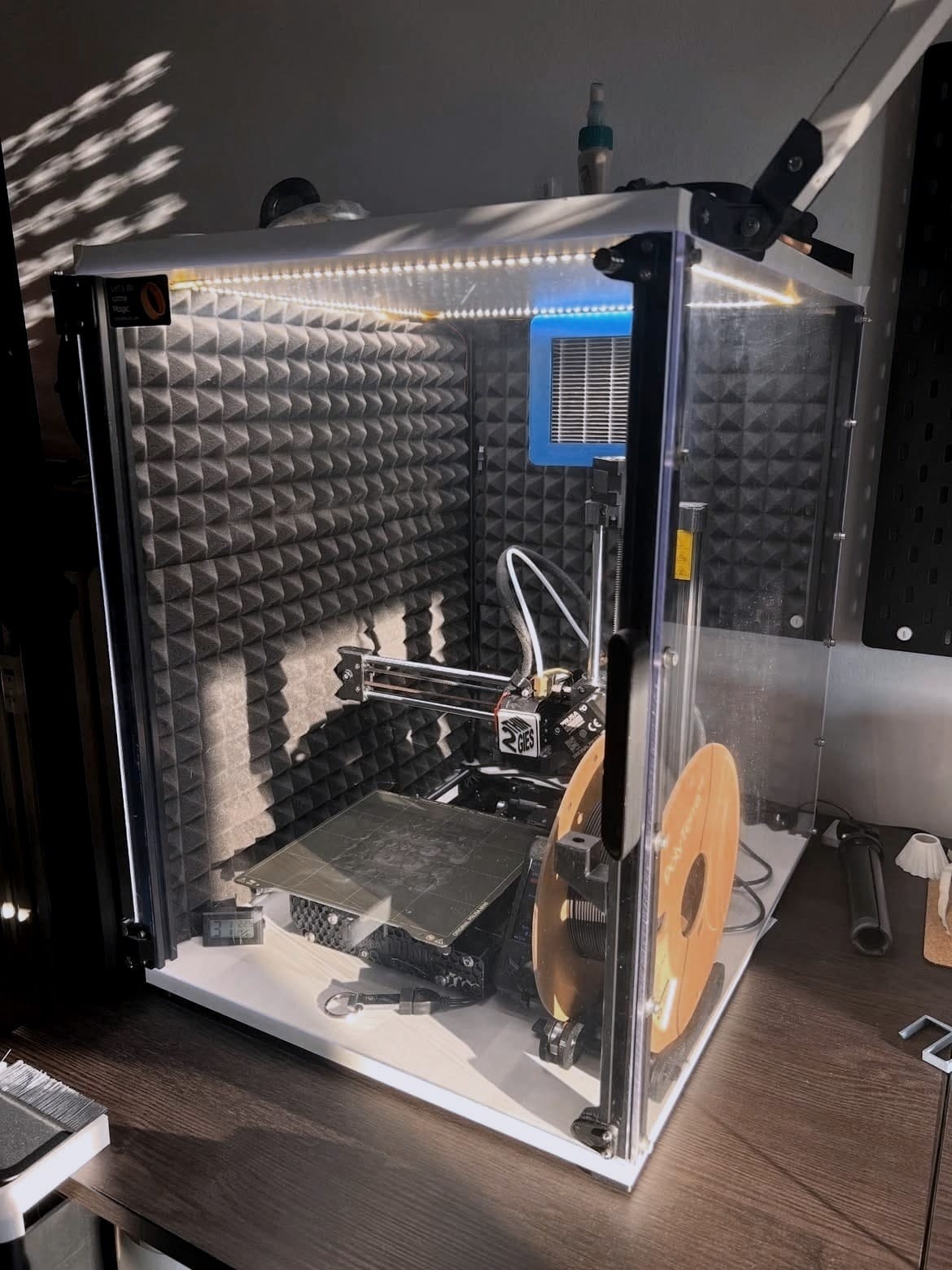

Since 2019, 3D printing has been my creative outlet—a way to keep making physical things in my spare time.

Even though I didn’t have much money and was living in a 36m² rental apartment, I started 3D printing with a small €170 printer in a tiny 1m² maker corner.

My tiny maker corner for 3 years

Suddenly, I didn’t need expensive CNC machines or a full workshop—the kind of setup I had worked with during university—to satisfy my need to create.

My background in Mechanical Engineering and the hands-on experience I gained from building race cars gave me a solid foundation for exploring what was possible with just a small 3D printer.

I had also worked as a Freelance CAD and rendering specialist online, before moving to Italy - which not only helped me develop useful skills but also gave me the chance to leave my home country and pursue a master’s degree in Europe.

However, after graduating, supporting my family in Venezuela and securing a new residence permit made stability a priority. Freelancing didn’t feel like a viable option, so I took the “safe” route and joined a multinational company.

Still, the desire to create never left me.

Showing creative work online

In the middle of all this, my partner and I started TwoThingies, a small creative outlet where we shared free 3D printable designs while we worked our day jobs.

We focused on functional, practical items—things that were meant to be used, not just admired on a shelf. It was incredibly rewarding to see people download, print, and actually enjoy the designs we made.

We drew inspiration from makers like Walter Hsiao, whose beautifully curated designs and stunning photography elevated everyday objects. We aimed to do the same.

Uri had a used CANON EOS1300D with kit lens EFS 18-55 mm. We both had CAD skills, Fusion 360 offered free licenses for hobbyists, and we invested in a small light box.

That was all we had, and it was more than enough.

Anyone who wants to start making can do it, even with little time, money or even space.

Some of the first designs my partner and I shared back in 2022. I liked designing stuff, she took amazing photos.

I was working a lot of extra hours in my job, so didn't have much spare time to sit down and design more elaborate things.

But just being able to print my ideas was very rewarding for me. So I kept doing it, from time to time. It was kind of therapeutic in some ways.

Things Design Studio: I launched an eCommerce in my spare time

In 2023, we finally moved to a larger apartment, with a room we could use as a shared studio. I could finally have an actual desk and started improving the studio and work setups using 3D-printed designs.

This process led me to begin prototyping and designing desk accessories I wanted but couldn’t find or afford. Using digital fabrication methods, I could make them in the apartment, ensuring the designs were sustainable and affordable.

I was bitten by the entrepreneurship bug and began thinking about turning this creative hobby into something more serious.

At first, I was afraid. How could I start a business while working full-time and barely scraping by? What if no one bought my designs—or worse, what if I couldn’t keep up with demand?

But then I realized I was asking the wrong questions. What if this actually worked? What if the ‘problems’ I was worried about, like too many orders, were the kind of problems worth solving? And what if I could learn the skills to make it all happen?

The excuses I told myself to avoid starting were illogical.

Starting this business had been on my mind for years—I had notebooks filled with designs, brainstormed ideas in the shower, imagined store setups on walks, and sketched late into the night.

The fact that I couldn’t stop thinking about it told me one thing: I had to try.

So I did.

In May of 2024, after years of dreaming and doubting, I registered a personal business. Things Designs Studio was born—a small step toward building something meaningful.

The more logical choice would have been an LLC or LTD, but in Italy, opening the equivalent (an SRL) costs you anywhere between €3000 and €5000 up front (of which about €2000 are just for the notary who registers it). Absurd.

Being an immigrant added another layer of complexity, as delays in my paperwork prevented me from legally selling online until October 2024. But instead of letting that stop me, I focused on preparation—streamlining processes, refining designs, and building systems so I could hit the ground running.

As of January 2025, my 3D printer has paid for itself, and the laser cutter (yes, I expanded my set of tools—I’ll tell you more about that later) is on track to do the same.

The store has been open for almost four months, with 50 sales, all from customers outside Italy—and more than half from outside Europe. I figured out international shipping from Europe, with shipping fees and taxes, though I still have some things to learn.

My partner is still by my side, and we support each other in our entrepreneurial endeavors. It's comforting because it's dangerous to go alone.

I’m excited to continue growing Things Design Studio—and to share every step of the journey with you.

What challenges are you facing in your own creative endeavors? Let’s figure them out together.

What’s Next?

Launching Things Design Studio was just the beginning of this journey. My goal isn’t just to create functional designs—it’s to build a brand, document the process, and share what I learn along the way.

Through my newsletter, Making Stuff After Office Hours, I’ll share behind-the-scenes insights into building a creative business while balancing a full-time job and personal responsibilities.

You’ll get to know the stories behind my favorite designs, the tools I use, the challenges I face, and the techniques I’ve honed to design and make things more efficient.

I’ll also explore what it’s like to run a small business in Europe and how digital fabrication is making entrepreneurship more accessible than ever.

If you’re a fellow maker, curious about 3D printing, laser cutting, design, and entrepreneurship—or just want to see what goes into building a small business from scratch—this is the place for you.

I hope my journey inspires you to start creating, too.