That's it: I'm getting a more reliable 3D printer

Let me tell you about my journey with a cheap 3D printer. It was a ton of fun, and I learned many useful things. Maybe you can learn from my errors too!

In 2019 I finally got my first hobby-grade, FDM 3D printer kit.

It was a Creality Ender 2, a cantilevered version of the successful Ender 3. It was the perfect fit for a small apartment, requiring a very reduced space to be installed on a desktop. I was really excited when it arrived, assembled it in 30 minutes, and started printing right away. The result of the first print turned out to be a decapitated version of the iconic Maneki-Neko cat, since the filament sample that came with the printer was not enough to complete the test .gcode file. I ended up modeling a head to fit the incomplete print and shared it online so that other fellow makers could use it as well.

At the time, all I wanted to do was to learn more about 3D printing, mod and upgrade my small Ender 2 and see how I could get the best out of such a cheap machine. I was still at university, completing my master's degree and I had just started working as a research assistant in the Aerosol Technology Laboratory. I had time to tinker around with the printer, right?

I had no idea what I was getting into.

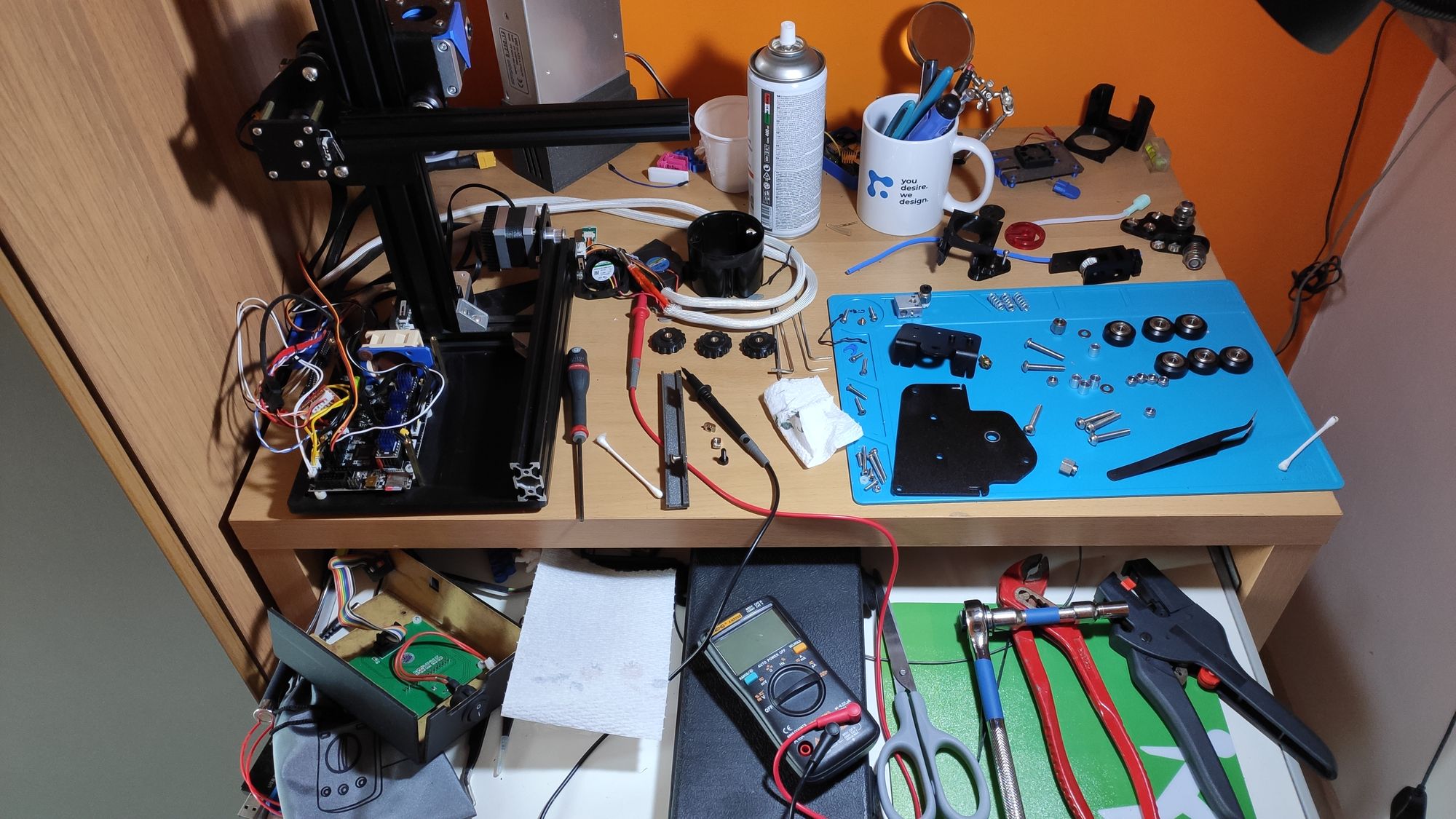

The printer became a Frankenstein and a learning project for me. I switched the printer's 8-bit mainboard for a 32-bit aftermarket one, upgraded the firmware, and installed a part-cooling fan and motor dampers: My first goal was to make it quieter.

Then I wanted to improve the print quality, so started buying other "budget upgrades", like a Bondtech BMG knock-off from AliExpress. You see, all the parts I was installing were usually sourced from China, so they were cheap, and took ages to arrive. But buying cheap parts for a cheap printer meant that I wasn't spending much after all... right? After all, it was working just as well as a much more expensive printer. What's a couple of euros here and then to make the machine work better? A new print surface to improve bed adhesion. A new set of PTFE tube couplers because the original ones broke...

But buying cheap parts for a cheap printer meant that I wasn't spending much after all... right?

Reliability

It was all good until I started actually wanting to use the printer more consistently during the 2020 COVID-19 lockdown. I printed a bunch of parts for the laboratory I was working on - since we had the equipment, we rushed to provide pre-certification tests for community face masks. Precisely then, I started having serious problems with the prints not adhering to the print bed. I couldn't launch a print and walk away without having to check every 10 seconds on whether the first layer was OK or not.

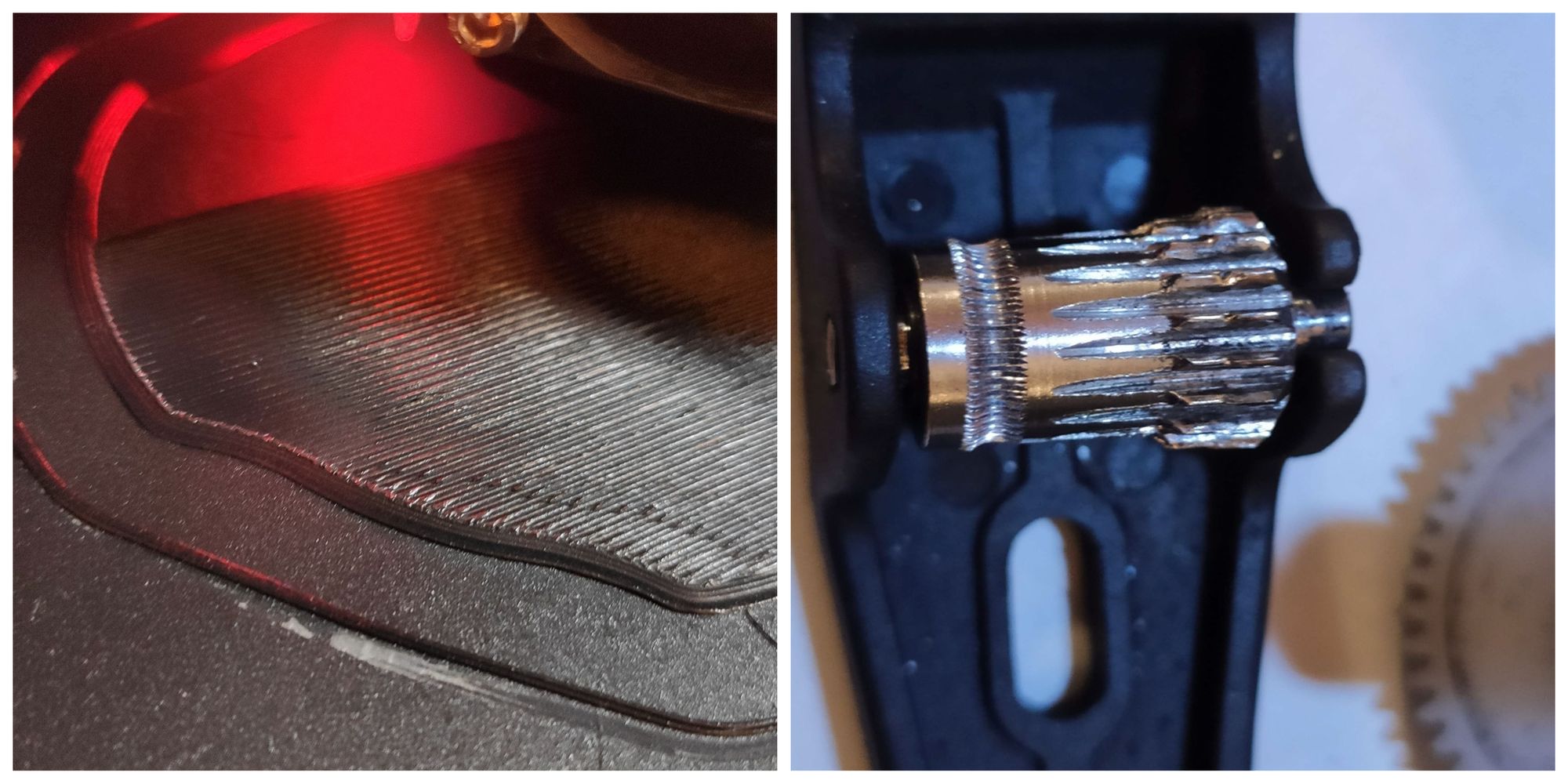

I tried every imaginable solution and read every possible Reddit thread or forum entry about similar problems. Tried different filaments, with different temperatures. Tested different combinations of filaments and heated bed surfaces, and re-leveled the bed a million times. Until I figured out that the bed was warped, and I needed to compensate for that. So I installed an Auto Bed-Leveling Sensor (3D touch) which would probe the bed before each print to compensate for the warped bed. It only worked partially. Some sports were too close to the bed, some too far.

On top of that, the extrusion started to be very inconsistent. And for various reasons. Sometimes I would fix things by changing the slicer parameters. But at some point, even slicer changes wouldn't help, and I started to find issues with hardware components. One time it was the hot-end heated cartridge not being able to provide enough power. Later on, the extruder gears started making some noise and I found out they were super worn out.

When I look back at the orders for upgrades and replacement components I made through AliExpress, Amazon, 3D Jake and eBay combined, I realize that the total is € 314! That is almost twice the price I paid for the printer itself, and it's not including the time I spent working on it, and reading online to figure out how to solve the problems I found.

I made a list with all the components i bought for the printer, their price, intended use, and how effective those upgrades were.

Unfortunately, I have lost all the data I collected about noise levels, number of successful first layers, bed level meshes, and so on. But I still think the list can be useful for someone starting with 3D printing as I did.

It all comes down to what your plans are, and how you value your time and money

In retrospect, the process of calibrating and upgrading the old Ender 2 and "fighting" to make it work better was an invaluable learning experience for me. I followed a bunch of useful online guides and learned about how awesome the maker community is online. I now understand a lot more about how 3D printers work: the Marlin software, extruder types, motion systems, stepper motors, power supply units, and got a lot of experience with slicer parameters. It was really a ton of fun too.

So now, when someone asks me: "should I get a 3D printer? How much should I spend on it?", the answer is, of course, a big: it depends.

What do you want to use it for? If you need consistency out of the box, maybe even a cheap Creality machine will do. If you need reliability and quality out of the box, you'll need a bigger budget for sure.

If you just want the printer for hobby use, then ask yourself: Do I want to tinker with the printer as a hobby, and am I willing to spend time learning about how it works? or do I want to use the printer to produce parts for my actual hobby?

That's where I made the decision to get a new one. Now I just need something to print consistently, since I no longer have all the time I had as a student. Plus, the Ender 2 has been discontinued, which means that replacement parts are no longer being produced. This is especially bad for the warped heated bed which had me struggling for the last couple of months. For reference, look at this plot I made with the data from a G29 command (the glass bed was installed!):

For my current needs, I'd rather have a printer that just works to make stuff for my actual hobbies. I think I've learned the basics quite well now.

By the way, some people were interested in the code I used to make the plot shown above, so here is the python script and the mesh data - so you can see the format of the txt file :)